Roll-to-Roll Feeding System: Supports continuous processing, enhancing efficiency and reducing downtime. High Cutting Precision: Delivers precise cuts with minimal waste, ensuring clean edges. Versatile Material Compatibility: Capable of cutting a wide variety of materials, including textiles, films, plastics, and leather. User-Friendly and Automated: Simplifies operation with an intuitive control system and minimizes manual intervention for smooth, automated production. Cost and Time Efficiency: High-speed cutting and minimal maintenance contribute to significant cost savings and reduced turnaround time.

Learn More

1. High-Precision Visual Positioning: Intelligent visual recognition system with ±0.03mm accuracy ensures flawless cutting of complex graphics, eliminating manual alignment errors. 2. Large-Format Efficient Processing: 1600×1000mm workbench supports batch processing of acrylic, wood, leather, etc., boosting efficiency by 50%. 3. Versatile CO2 Laser Cutting: 30W–100W options easily cut non-metal materials like fabric, rubber, and plastic with smooth, burr-free edges. 4. Energy-Saving & Long-Lasting Stability: Air cooling reduces power use by 20%; industrial-grade laser tube offers up to 8000 hours of reliable operation.

Learn More

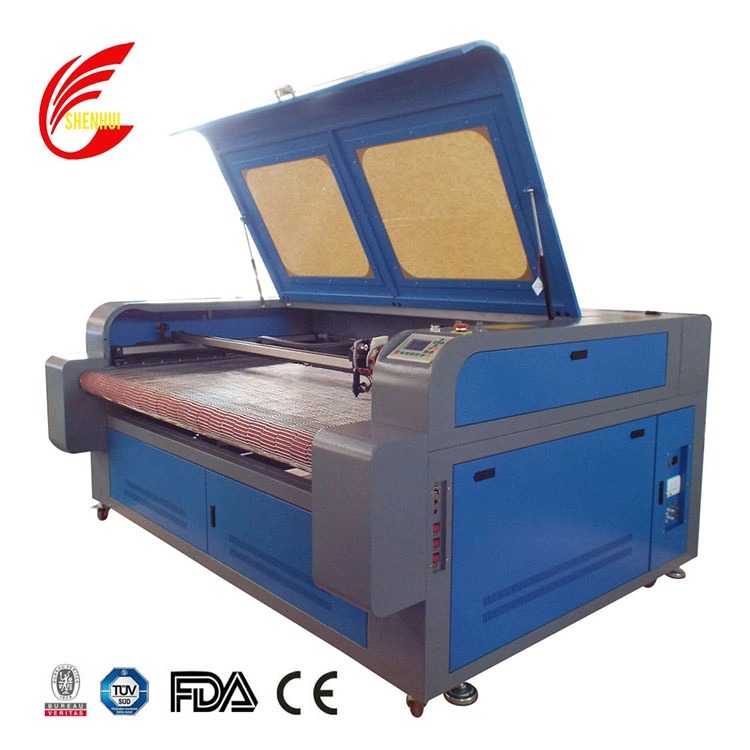

✅ Large processing range: 1300 × 2500mm large tabletop, easy to handle cutting of large format materials! ✅ High precision cutting: CO2 laser technology, smooth and burr free incision, accuracy up to ± 0.05mm! ✅ Widely applicable: wooden boards, acrylic, leather, fabrics, rubber... can be cut in one machine, cross cutting without pressure! ✅ Energy saving and environmental protection: Low energy design, pollution-free processing, saving money and worry! ✅ Intelligent operation: human-computer interaction interface, simple and easy to learn, even beginners can become experts in seconds!

Learn More